Their underlying message was that buying such a poor-quality vehicle would be a bad choice and a total waste of money.

One can always think of examples where low product quality represents acceptable value for money – for example, inexpensive garden furniture can be seen as a product that will be replaced frequently, thereby ‘saving’ on maintenance efforts and cost.

Leading principles

This is not a strategy that aligns with the leading principles of the “cost of poor quality” (COPQ) concept, which addresses the costs that would disappear if systems, processes and products were perfect.

COPQ is said to have been made popular by IBM quality expert H James Harrington in his 1987 book, Poor Quality Costs.

When designing products, considering the lifetime cost of poor quality is always essential, including for the wind industry, which requires first-class products with cost-effective optimal performance during their 25–30 year design life.

Offshore especially is an unforgiving environment where one inexpensive part leading to turbine failure might cause significant revenue loss if installations cannot be accessed for a prolonged period during adverse weather.

Facing pressure

Turbine suppliers without exception face enormous pressures to reduce turbine Capex and the levelised cost of energy (LCoE) while dealing with difficult market conditions.

Outside China, low turbine prices have created unsustainable conditions for suppliers. But major conceptual changes have been limited so far – except for Vestas, which introduced a fully integrated EnVentus onshore medium-speed drivetrain in early 2019, and an enhanced version for the offshore class two years later.

In response to the end of state subsidies for onshore wind from 31 December 2020 and for offshore wind a year later, Chinese suppliers came up with a series of conceptual and other changes.

They fitted much larger rotors for given ratings and introduced drivetrain concept switches – with Goldwind moving (almost) completely from direct drive to medium-speed geared for both onshore and offshore, while MingYang, among others, introduced new high-speed geared onshore models with a doubly fed induction generator (DFIG) in a move away from medium-speed models.

Conceptual changes should not be seen as a silver bullet towards fresh business fortunes, however, but must always be the outcome of careful evaluation focused on creating long-term added value for turbine clients.

Reducing costs

The head of a renewables insurance firm recently told Windpower Monthly that all turbine manufacturers had been focused on reducing costs in order to compete. This in turn, he said, was “compromising the quality and performance of components and contractors”.

He argued that an “unprecedented number of mechanical breakdowns, component failures and serial defects are harming turbine makers’ profits and squeezing their suppliers”. In conclusion, he said that the wind sector “needs to recognise that cutting corners on quality will ultimately undermine its competitiveness and sustainability”.

There have been several reports of quality-related problems – with issues typically described in blurred, rather meaningless, phrases such as “certain components”, “new forms of failures”, “vibrations and bearings”, “blades and bearings”, and “unacceptable warranty provisions tied to repairs and upgrades”.

In search of clues and the wider significance of actual root causes, I have often asked myself what to make of such messages, including the extent of specific failures, and where to look for possible solutions without entering into speculation.

Such specific questions must focus on whether certain issues would apply to single or multiple main components, stay within or extend across a supplier’s turbine platforms, and/or full-turbine model level(s) and/or dedicated supply chain(s).

Communication

More often than not manufacturers today, including the OEMs, often fail to use clear, fact-based language when communicating with concerned stakeholders, which inevitably backfires by giving way to rumours and speculation.

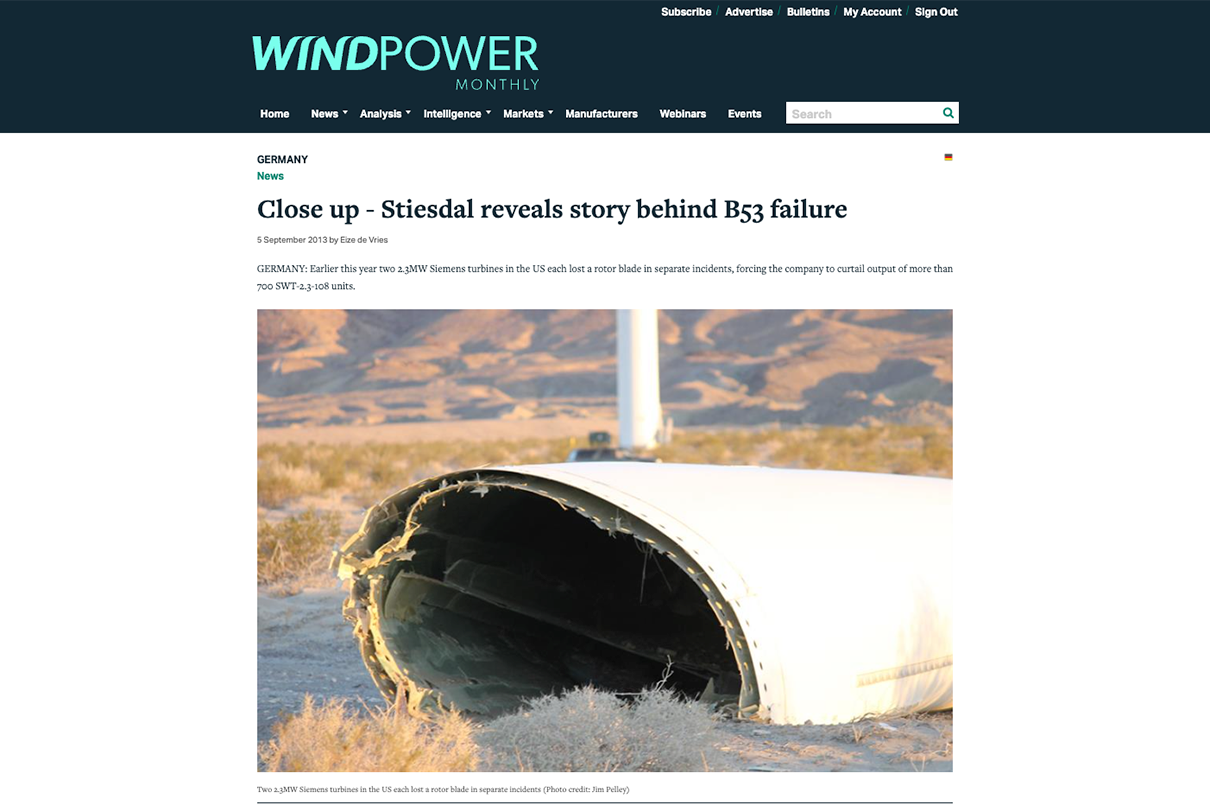

One really good example of how this can be avoided is how Siemens Wind Power handled a 2013 issue involving two 2.3MW turbines – each having lost a blade in separate incidents, forcing the company to temporarily curtail the output level of some of its 700-strong fleet of SWT-2.3-108 units.

Later that year, Henrik Stiesdal, then Siemens Wind Power chief technology officer, explained in detail the outcomes of a root cause analysis, how an upgrade for existing blades was going to fix the problem, and shared details on design modifications for newly manufactured blades.

Pondering on the possible negative impact of the issue, Stiesdal said: “Technology failures always hurt your pride. However, once we had the issue we demonstrated that we were capable of successfully addressing a complex failure issue and implementing solutions conservatively.

Hidden failure costs

COPQ literature is very clear in stating that while quality-related costs, if unmeasured, might remain initially hidden, they re-emerge in internal and external failure costs eroding an organisation’s financial base and, in some cases, seriously impacting future prospects.

Typical COPQ-related examples of both cost categories include remedying defects, re-work, unscheduled lost time, scrapped components, customer complaints, higher warranty claims, reputation loss, liabilities and ultimately the risk to business survival itself.

An irreversible consequence of false hope and failure to notice ongoing signs of changing times, reinforced by hubris and conservatism, is exemplified by the rise and fall of the legendary British Norton motorcycle brand. It rose from the ashes in the 1980s through several incarnations, but lacking commercial successes had to be rescued from collapse again in 2020 by India’s TVS Motors.

Founded in 1898, the brand’s reputation rose quickly, boosted by racing triumphs and business success. A prominent postwar bike model was the flagship 500cc Norton Dominator of 1949.

In line with British motorcycle design tradition, it featured a parallel two-cylinder four-stroke engine with pistons moving up and down together, offering even firing intervals and the characteristic roaring exhaust sound.

Norton and other famous British competitors like Triumph typically used cast-iron cylinder housings and a crankshaft supported by two outer bearings and a balancing counterweight in between.

The crankshaft support principle can be compared to a beam supported at each end plus a centrally located load. With unchanged beam properties, deflection tends to grow when the distance between the supports increases – and/or when applying heavier loads. This translates into an inherent concept disadvantage for British parallel twin engines, causing heavy vibrations and “characteristic” oil leaks.

Vibration cause

With crankshaft deflection already contributing to vibrations at the initial engine size, the problem was amplified by two parallel performance-boosting measures: the engineers raised the engine’s rotational speeds and increased the engine’s displacement to 650cc in 1960 and 750cc two years later. In the latter scaling, pistons were enlarged with unchanged stroke length.

1974 Norton Commando Interstate 850cc. (pic credit: National Motor Museum/Heritage Images/Getty Images)

These changes contributed to increased crankshaft deflection and worsening vibrations. Norton’s final motorcycle product development became the Commando, praised for its elegant looks and described as the world’s first superbike, and produced in two variants between 1967 and 1977. It featured an innovative “isolastic frame” isolating the driver and the frame from engine vibrations.

The initial Commando 750 featured an uprated 745cc engine of a late 1940s design, while development of two further engine concepts – having drained the company’s financial resources – was discontinued.

In its final days, the company introduced an uprated 828cc engine in a model called the Commando 850 interstate. However, the Commando 750 and 850 engine and the original ‘isolastic frame’ approach both suffered from many issues.

The Commando concept succeeded in isolating vibrations from frame and rider but – crucially – not in eliminating the inherent causes and all associated harmful impacts to engine reliability and O&M demand.

In summary, infamous dependencies inherent to the ‘old’ engine concept were enhanced during each scaling step: this created a situation where the introduction of each new solution led to new issues elsewhere.

The first step taken was to minimise the crankshaft bearing distance, in order to curb deflection and control vibrations. But this conflicted with a second demand for creating sufficient “flesh” between the pistons – for sound integrity and temperature management.

Historical sources suggest that Norton tried to resolve the negative impact of thermal issues such as cylinder linings becoming oval through increased piston-cylinder tolerance.

Law of conservation of misery

In accordance with the ‘law of conservation of misery’, which states that the total amount of misery remains the same or even increases without essential and fundamental problem-solving measures taken, the outcomes were as could be expected: faster engine wear, higher oil consumption and loss in engine efficiency and product quality – all things that every engineer strives to avoid at all times.

The misery was compounded by false hope in a “bigger is better" strategy aimed at holding off Japanese competitors such as Honda, which had entered the market with smaller bikes equipped with modern, high-performance engines.

As these models became increasingly popular, the great conservative British manufacturers including Norton – unwilling to change when they could – ended up lacking the financial means to change course: most were driven to the brink of extinction.

While wind turbines are in many respects different from motorcycles, the rise and fall of Norton is a salutary lesson on what can go wrong when quality-related issues are not addressed.

The key message for both is to never compromise on quality. It is also important to note that initially sound concepts may not stay that way indefinitely as further development steps are taken.

If hidden issues at components level occur at the outset, they (and known interdependencies) must be addressed with urgency before they reach full systems level and start sliding towards poor overall quality – or worse.

If this does not happen, there are no easy or inexpensive remedies within reach. The only available remedy is to reach out for costly radical solutions. If taken up in a timely and vigorous manner, they could perhaps have prevented Norton’s sad but avoidable ending.

(1)-2.png)

.png)

.png)

.jpg)